Maintenance and Asset Care Department Organization for Manufacturing Industries

In Maintenance and Asset Care Department Organization for Manufacturing Industries, you'll learn ...

- The mission and objectives and the critical role of a well-functioning of a Maintenance/Asset Care Organization

- Essential Key Performance Indicators (KPIs) used to measure the effectiveness of Maintenance Organizations

- Common organizational structures for Maintenance/Asset Care teams, analyzing why certain structures contribute to technical success and operational efficiency.

- Best practices in Maintenance/Asset Care—including Total Productive Maintenance (TPM), with a focus on their practical applications.

Overview

The course will begin with an overview of the mission and objectives of a Maintenance/Asset Care Organization. This section will emphasize the critical role of a well-functioning maintenance organization by showcasing historical catastrophic failures and their associated human and economic impacts.

Next, the course will provide an in-depth look at the Skilled Trades professionals within a Maintenance Organization. It will cover key roles such as Maintenance Mechanics, PLC Technicians, Electromechanical Technicians, Facilities Technicians, Reliability Engineers, MRO Purchasers, and Stockroom Attendants, detailing their required skillsets and typical training backgrounds.

A discussion on essential Key Performance Indicators (KPIs) used to measure the effectiveness of Maintenance Organizations will follow.

The course will then explore common organizational structures for Maintenance/Asset Care teams, analyzing why certain structures contribute to technical success and operational efficiency.

Subsequently, best practices in Maintenance/Asset Care—including Total Productive Maintenance (TPM)—will be examined in detail, with a focus on their practical applications.

Finally, the course will conclude with a summary of key takeaways, reinforcing the importance of a high-functioning maintenance organization and how strategic investment in this critical technical function drives long-term success in manufacturing.

Specific Knowledge or Skill Obtained

This course teaches the following specific knowledge and skills:

- The mission and importance of Maintenance and Asset Care Departments within manufacturing and distribution environments, including how they impact operational performance and profitability.

- The difference between traditional Maintenance and holistic Asset Care approaches, and why modern organizations are transitioning to proactive maintenance strategies.

- The roles and responsibilities of key personnel within a Maintenance and Asset Care team, including Managers, Supervisors, Technicians, and Planners.

- The value of preventive and predictive maintenance and its impact on minimizing unplanned downtime and enhancing equipment reliability.

- How to interpret an example organizational chart for a Maintenance and Asset Care team and understand how different roles interact within the structure.

- The significance of historical failures (e.g., Imperial Sugar explosion) in highlighting the critical role of effective maintenance practices.

- Common qualifications, training pathways, and best practices for technical roles such as PLC Technicians, Utilities Technicians, and MRO Stockroom Associates.

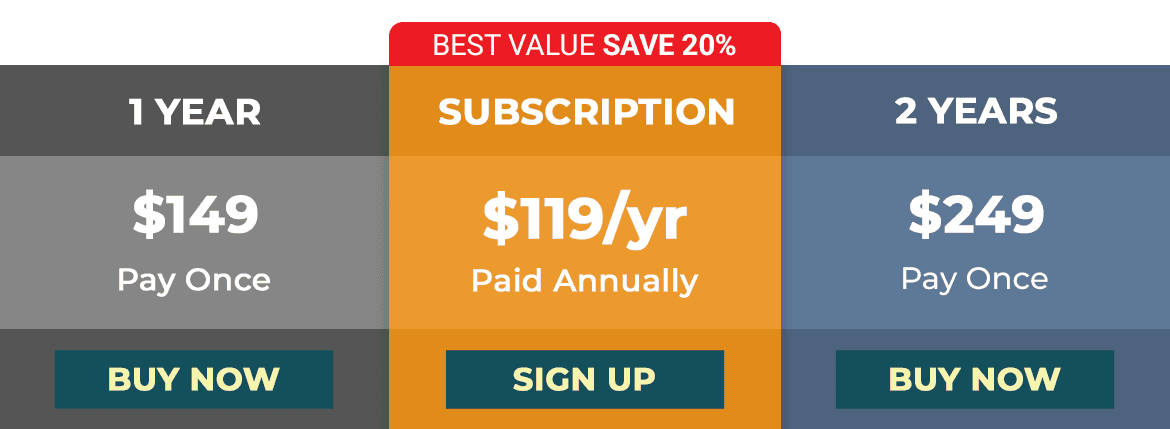

Certificate of Completion

You will be able to immediately print a certificate of completion after passing a multiple-choice quiz consisting of 10 questions. PDH credits are not awarded until the course is completed and quiz is passed.

| This course is applicable to professional engineers in: | ||

| Alabama (P.E.) | Alaska (P.E.) | Arkansas (P.E.) |

| Delaware (P.E.) | District of Columbia (P.E.) | Florida (P.E. Area of Practice) |

| Georgia (P.E.) | Idaho (P.E.) | Illinois (P.E.) |

| Illinois (S.E.) | Indiana (P.E.) | Iowa (P.E.) |

| Kansas (P.E.) | Kentucky (P.E.) | Louisiana (P.E.) |

| Maine (P.E.) | Maryland (P.E.) | Michigan (P.E.) |

| Minnesota (P.E.) | Mississippi (P.E.) | Missouri (P.E.) |

| Montana (P.E.) | Nebraska (P.E.) | Nevada (P.E.) |

| New Hampshire (P.E.) | New Jersey (P.E.) | New Mexico (P.E.) |

| New York (P.E.) | North Carolina (P.E.) | North Dakota (P.E.) |

| Ohio (P.E. Self-Paced) | Oklahoma (P.E.) | Oregon (P.E.) |

| Pennsylvania (P.E.) | South Carolina (P.E.) | South Dakota (P.E.) |

| Tennessee (P.E.) | Texas (P.E.) | Utah (P.E.) |

| Vermont (P.E.) | Virginia (P.E.) | West Virginia (P.E.) |

| Wisconsin (P.E.) | Wyoming (P.E.) | |