Supplementary Cementitious Material (SCM)

Credit: 1 PDH

Subject Matter Expert: Mark Knarr, P.E., CDT, CEM, LEED AP BD+C, PMP, CCEA, GPCP

In Supplementary Cementitious Material (SCM), you'll learn ...

- What is SCM and why is it sometimes used as a partial substitute for Portland cement

- How SCMs used with ordinary Portland cement (OPC) can improve concrete properties in both the fresh and hardened state, beyond what is achievable with just OPC

- Various types of SCMs, along with their specifications and performance characteristics

Overview

Concrete is a combination of water, aggregate, and – of course – hydraulic cement. Portland cement is the most common hydraulic cement for casting concrete. However, production of portland cement is highly energy intensive, relying on combustion to heat kilns to about 2,700°F in order for raw materials to chemically react. Such combustion consumes thousands of British thermal units (BTU’s) to yield a ton of portland cement. Not only does this require vast quantities of non-renewable fuels, but the products of combustion – such as CO2 and particulate matter – must be treated to ensure compliance with air quality codes.

Fortunately, there are other inorganic materials available from both natural sources and industrial waste streams that can partially replace portland cement in the mix. Such materials are called supplementary cementitious materials (SCMs). Substituting a portion of portland cement with SCM lowers the demand for portland cement, which in turn grants an opportunity to shrink the environmental footprint in manufacturing new material.

Aside from being a sustainable alternative to portland cement, SCMs can reduce the cost of mix materials and – more importantly – yield a better product in terms of workability, durability, or compressive strength.

This course is intended for civil or transportation engineers who are interested in construction of portland concrete pavement, particularly in materials selection.

Specific Knowledge or Skill Obtained

This course teaches the following specific knowledge and skills:

- Benefits of SCMs: performance and sustainability

- SCMs from industrial sources: fly ash, slag cement, and silica fume

- SCM from natural sources: metakaolin

- Chemical reactions in water: hydraulic vs. pozzolonic

- Effects of SCMs on concrete in its fresh or hardened state

- SCM specifications

- SCMs as effective deterrents of alkali-silica reaction (ASR)

Certificate of Completion

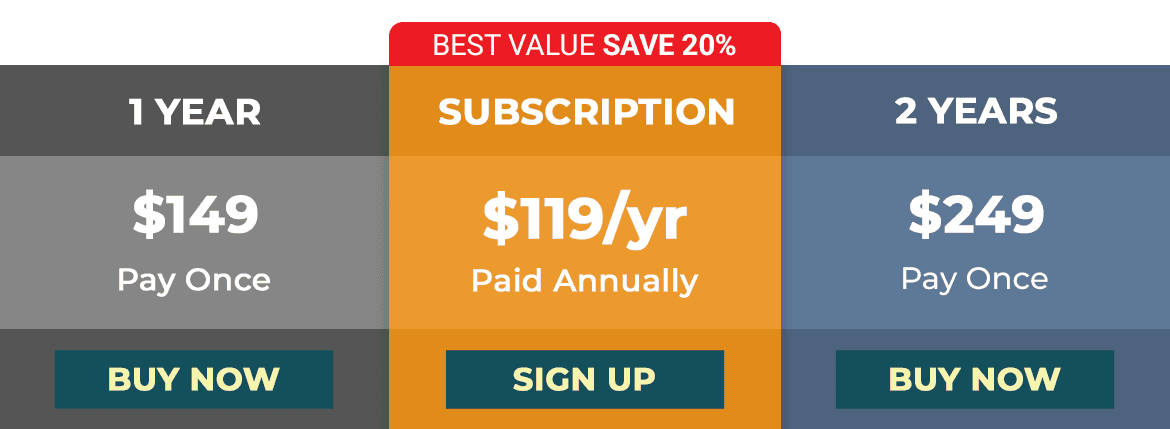

You will be able to immediately print a certificate of completion after passing a multiple-choice quiz consisting of 10 questions. PDH credits are not awarded until the course is completed and quiz is passed.

| This course is applicable to professional engineers in: | ||

| Alabama (P.E.) | Alaska (P.E.) | Arkansas (P.E.) |

| Delaware (P.E.) | District of Columbia (P.E.) | Florida (P.E. Area of Practice) |

| Georgia (P.E.) | Idaho (P.E.) | Illinois (P.E.) |

| Illinois (S.E.) | Indiana (P.E.) | Iowa (P.E.) |

| Kansas (P.E.) | Kentucky (P.E.) | Louisiana (P.E.) |

| Maine (P.E.) | Maryland (P.E.) | Michigan (P.E.) |

| Minnesota (P.E.) | Mississippi (P.E.) | Missouri (P.E.) |

| Montana (P.E.) | Nebraska (P.E.) | Nevada (P.E.) |

| New Hampshire (P.E.) | New Jersey (P.E.) | New Mexico (P.E.) |

| New York (P.E.) | North Carolina (P.E.) | North Dakota (P.E.) |

| Ohio (P.E. Self-Paced) | Oklahoma (P.E.) | Oregon (P.E.) |

| Pennsylvania (P.E.) | South Carolina (P.E.) | South Dakota (P.E.) |

| Tennessee (P.E.) | Texas (P.E.) | Utah (P.E.) |

| Vermont (P.E.) | Virginia (P.E.) | West Virginia (P.E.) |

| Wisconsin (P.E.) | Wyoming (P.E.) | |