Introduction to Facility Operability – How to Design Operable Facilities

In Introduction to Facility Operability – How to Design Operable Facilities, you'll learn ...

- Why any facility that will be operated by people should have “Facility Operability” designed in

- How RAM Analysis can be used to help design an operations organization, as well as a facility

- Equipment reliability and how to determine reliability for various system configurations

- How Facility Operability can be enhanced by the use of project management tools

Overview

This course is based on the author’s extensive experience in upstream oil and gas producing operations and capital project support. However the techniques presented will have applications in many industries. Any facilities that will be operated by people should have “Facility Operability” designed in. These facility operability activities should start early in the capital project process and grow with the project to achieve a seamless handover of the facilities to a safe, sustainable business venture.

Many of the usual project tools are discussed and re-cast in the light of how they can support Facility Operability – plus a few new tools! The value of RAM (Reliability, Availability, Maintainability) Analysis cannot be overstated. This course demonstrates how RAM Analysis can be used to help design an operations organization as well as a facility. This is a very powerful and intriguing application of RAM. This introduction to RAM should get the student(s) thinking of many other uses for this tool.

The concept of equipment reliability is discussed, and then expanded to determining reliability for various system configurations. Several system examples are presented to move from the theoretical to the practical. Methods for interpreting a RAM Analysis are presented – including using an Availability Graph to determine system availability at a given confidence level, and how to use Tornado Graphs to identify availability improvement opportunities. Again, examples are used to move from the theoretical to the practical.

Finally, the course presents how Facility Operability can be enhanced by some of the usual project management tools. Specific “Facility Operability” activities are discussed, as are several Key Success Factors. The course is filled with graphical depictions and practical examples. It is intended to be interesting, fun, and filled with practical ideas that can be quickly implemented by students. The course can also serve as a reference for future use.

Specific Knowledge or Skill Obtained

This course teaches the following specific knowledge and skills:

- How to keep the business’ value proposition at the core of the design process

- The role of Facility Operability in supporting a sustainable business by enhancing safety, efficiency, and profitability

- How the project stage process can be used to enhance Facility Operability

- The importance of considering Facility Operability early in the capital project process

- The power and flexibility of the RAM (Reliability, Availability, Maintainability) Analysis as a Facility Operability tool as well as a facility design tool

- The definitions of Failure Rate, Reliability, Mean Time To Failure (MTTF), and Mean Time To Repair (MTTR) – and how they relate to one another

- How to calculate reliability for equipment and for various system configurations

- The various factors that affect Mean Time To Failure (MTTF) and Mean Time To Repair (MTTR)

- The definition of Availability

- How a RAM Analysis is performed

- How to use RAM Analysis at various project stages

- How to interpret and use the output of a RAM Analysis

- How to develop a Design Basis, and the importance of the initial Value Proposition

- How to develop various Project Guidance Documents (philosophies, specifications, and plans) and how they can help achieve Facility Operability

- How RAM Analysis can assist in the preparation of project philosophies, specifications, and plans

- The different focuses of an Equipment reliability program and a Facility Integrity program

- How several operability-related studies can be enhanced to improve effectiveness

- How to use the CDC’s Hierarchy of Controls to evaluate risk mitigation strategies

- How several Key Success Factors have proven to help achieve Facility Operability

Certificate of Completion

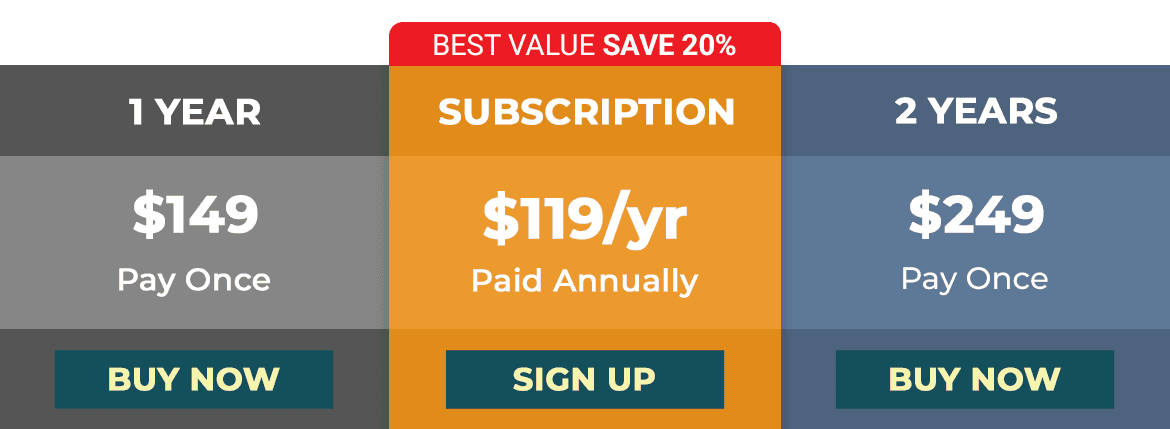

You will be able to immediately print a certificate of completion after passing a multiple-choice quiz consisting of 30 questions. PDH credits are not awarded until the course is completed and quiz is passed.

| This course is applicable to professional engineers in: | ||

| Alabama (P.E.) | Alaska (P.E.) | Arkansas (P.E.) |

| Delaware (P.E.) | District of Columbia (P.E.) | Florida (P.E. Area of Practice) |

| Georgia (P.E.) | Idaho (P.E.) | Illinois (P.E.) |

| Illinois (S.E.) | Indiana (P.E.) | Iowa (P.E.) |

| Kansas (P.E.) | Kentucky (P.E.) | Louisiana (P.E.) |

| Maine (P.E.) | Maryland (P.E.) | Michigan (P.E.) |

| Minnesota (P.E.) | Mississippi (P.E.) | Missouri (P.E.) |

| Montana (P.E.) | Nebraska (P.E.) | Nevada (P.E.) |

| New Hampshire (P.E.) | New Jersey (P.E.) | New Mexico (P.E.) |

| New York (P.E.) | North Carolina (P.E.) | North Dakota (P.E.) |

| Ohio (P.E. Self-Paced) | Oklahoma (P.E.) | Oregon (P.E.) |

| Pennsylvania (P.E.) | South Carolina (P.E.) | South Dakota (P.E.) |

| Tennessee (P.E.) | Texas (P.E.) | Utah (P.E.) |

| Vermont (P.E.) | Virginia (P.E.) | West Virginia (P.E.) |

| Wisconsin (P.E.) | Wyoming (P.E.) | |