Characteristics and Properties of Metals

In Characteristics and Properties of Metals , you'll learn ...

- The five types of bonding that occur in materials and their characteristics

- Distinguishing characteristics and properties of the three most common types of crystalline or lattice structures in metals

- Important factors to consider when selecting materials, including physical properties, heat treatment, corrosion, and hydrogen embrittlement

- How to identify microscopic imperfections and macroscopic defects in metals

Overview

Understanding the structure and properties of metals helps engineers determine their usefulness for a specific application. For example, knowing the ability of a metal or material to react to variable forces (loads) is of particular importance. Mechanical engineers calculate these forces to establish the service that can be expected and material scientists experiment to determine how metals deform (elongate, compress, and twist) or break as a function of applied load, time, temperature, and other conditions.

This course explains the basic structure and properties of metals, which is critically important when identifying the most appropriate metal to use for each application. It also discusses how metals are affected by various processes, imperfections, or defects.

Specific Knowledge or Skill Obtained

This course teaches the following specific knowledge and skills:

- The nature of five types of bonding that occur in materials and their characteristics

- The three most common types of crystalline structures: Body-centered cubic structure; Face-centered cubic structure; and Hexagonal close-packed structure

- Common characteristics of alloys

- The three types of microscopic imperfections found in crystalline structures

- How to distinguish between tensile, compressive, and shear stresses

- Two common forms of strain: elastic strain and plastic deformation

- Hooke's Law and Young's Modulus (Elastic Modulus) as it relates to stress

- How to interpret a stress-strain curve for: Application of Hooke's Law; Elastic region; Plastic region

- Important physical properties of metals, such as strength, ultimate tensile strength, yield strength, ductility, malleability, toughness, and hardness

- The effects on ductility caused by temperature changes, irradiation, and cold working

- How heat treatment affects the properties of heat-treated steel and carbon steel

- The reason that galvanic corrosion is a concern in design and material selection

- The two required conditions for hydrogen embitterment and its formation process

Certificate of Completion

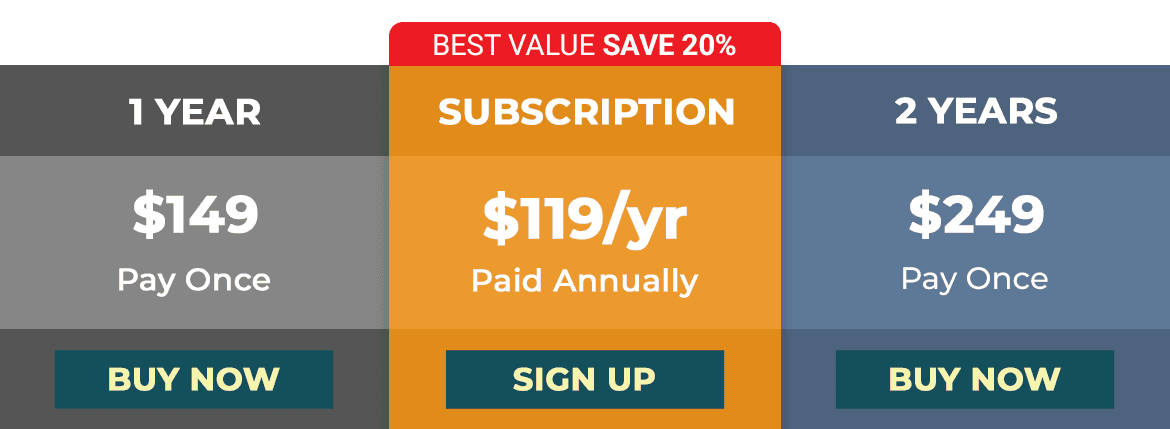

You will be able to immediately print a certificate of completion after passing a multiple-choice quiz consisting of 40 questions. PDH credits are not awarded until the course is completed and quiz is passed.

| This course is applicable to professional engineers in: | ||

| Alabama (P.E.) | Alaska (P.E.) | Arkansas (P.E.) |

| Delaware (P.E.) | District of Columbia (P.E.) | Florida (P.E. Area of Practice) |

| Georgia (P.E.) | Idaho (P.E.) | Illinois (P.E.) |

| Illinois (S.E.) | Indiana (P.E.) | Iowa (P.E.) |

| Kansas (P.E.) | Kentucky (P.E.) | Louisiana (P.E.) |

| Maine (P.E.) | Maryland (P.E.) | Michigan (P.E.) |

| Minnesota (P.E.) | Mississippi (P.E.) | Missouri (P.E.) |

| Montana (P.E.) | Nebraska (P.E.) | Nevada (P.E.) |

| New Hampshire (P.E.) | New Jersey (P.E.) | New Mexico (P.E.) |

| New York (P.E.) | North Carolina (P.E.) | North Dakota (P.E.) |

| Ohio (P.E. Self-Paced) | Oklahoma (P.E.) | Oregon (P.E.) |

| Pennsylvania (P.E.) | South Carolina (P.E.) | South Dakota (P.E.) |

| Tennessee (P.E.) | Texas (P.E.) | Utah (P.E.) |

| Vermont (P.E.) | Virginia (P.E.) | West Virginia (P.E.) |

| Wisconsin (P.E.) | Wyoming (P.E.) | |